GreenBlow applications in the ceramic sector

allow for cooling, drying and cleaning with low energy impact

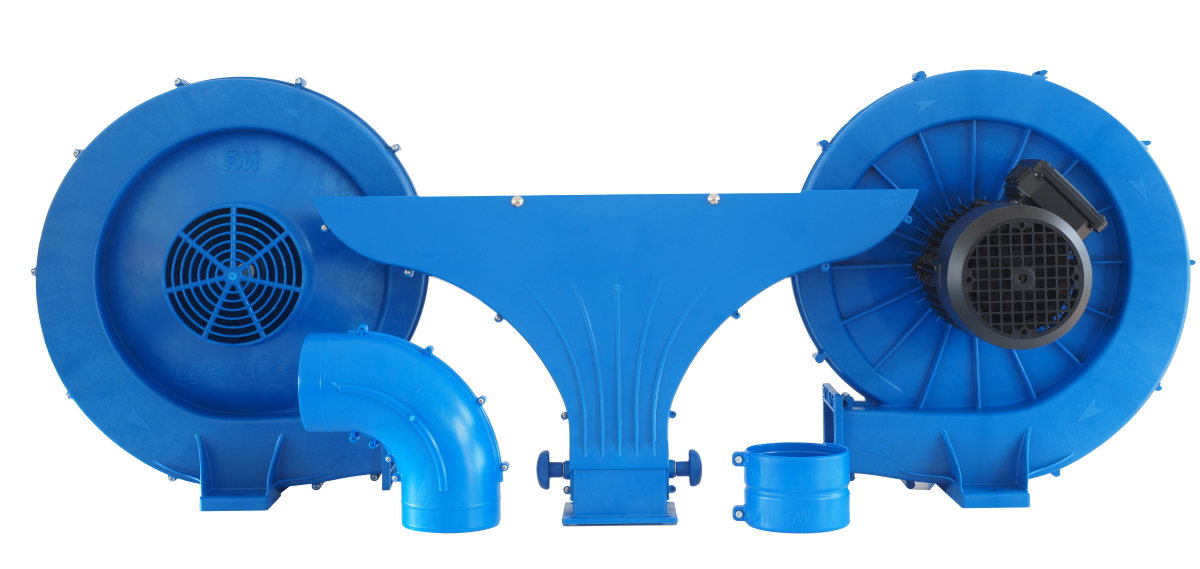

Blowers, diffusers, air knives and a lot of components useful to create a blowing system (suction and filetring) that allows to solve different sector applications.

COOLING

The digital tile printing process, in order to be effective, needs two fundamental conditions:

– receive the tile at a temperature compatible with the printer;

– absence of surface steam which could damage the print heads.

For these reasons, the cooling process of the tiles before the digital printer is essential to obtain an optimal printing result, limit production waste but also preserve the expensive print heads.

The combination of multiple air knives powered by GreenBlow blowers solves the application effectively with low energy consumption.

More info about this application available HERE

DRYING

Also in this appication, a correct and effectively drying of the product after cutting or post-lapping operations, is essential.

Also in this appication, a correct and effectively drying of the product after cutting or post-lapping operations, is essential.

By using highly efficient, low energy GreenBlow air knives and blowers, it is possible to create a system that can dry both the upper and lower part of the product, in a very small space.

More info about this application available QUI

CLEANING

With the PULL’n’CATCH® system it is possible to aspirate and air filter, eliminating dust and processing residues.

A second stage of filtration, thanks to the use of HEPA filters, limits the diffusion and inhalation of potentially carcinogenic substances such as PM2.5 and PM10, crystalline free silica, also favoring the elimination of bacteria and viruses (including Covid-19 ).

A simple, autonomous system that keeps a small space on the line that allows to be inserted at any point of the line, such as kiln entrance, before a cooling system, etc…

More info about the system HERE

System Presentation Video HERE

A “tailor-made” product

The range of components of the GreenBlow line: blowers, air knives (up to over 4 metres), connectors, brackets and supports, allow you to create a customised application, easy to install on all systems (even existing ones), with limited space and with practically zero maintenance costs.

No specialized technicians are required for either installation or maintenance.

General characteristics of the GreenBlow® Line

GreenBlow® Line has unique characteristics as it combines blowers with motors at high efficiency and low energy impact.

The accessories that are part of the line, together with air knives and diffusers (custom designed for the blowers) are able to offer high speed air flows with minimum pressure drops.

These features are essential for even complex applications, without forgetting low energy impact and high efficiency.

Exhibitions of the Sector

Contact us for specific consultation about your application or come and visit us at the trade fairs scheduled for Autumn:

- TECNA – Rimini (Italy), from 24th to 27th september, near our stand – Pavillon D1, Stand 100

On the site you can see other applications in the ceramic and marble, glass sector

What applications can be seen ?

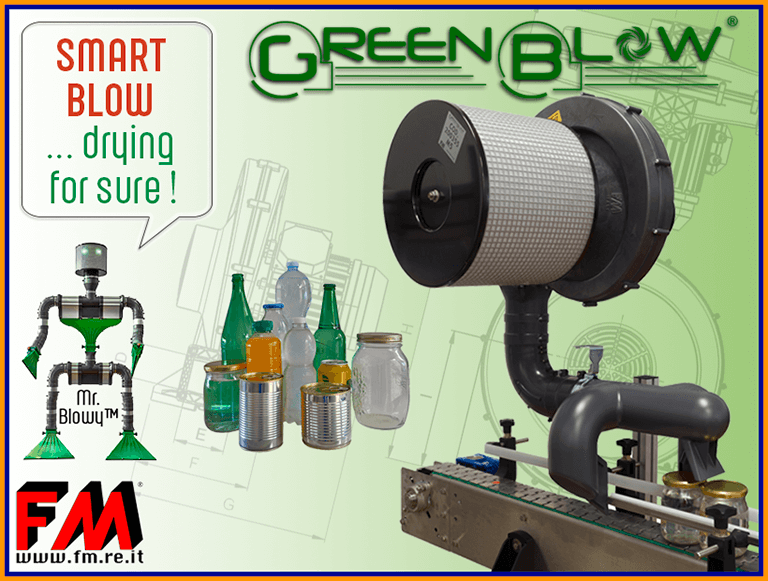

What applications can be seen ? Before the product labeling or marking phase, it is essential to obtain effective drying of the container also to ensure correct storage of the product before sale.

Before the product labeling or marking phase, it is essential to obtain effective drying of the container also to ensure correct storage of the product before sale.

kegs: (e.g. beer kegs) the air knife can cover the entire surface of the container or concentrate on a specific part, e.g. to dry the marking area.

kegs: (e.g. beer kegs) the air knife can cover the entire surface of the container or concentrate on a specific part, e.g. to dry the marking area.

Be it wines, spirits, fruit juices or any bottled liquid, drying before the labeling stage is essential. Furthermore, removing the water residues under the cap allows for perfect conservation in stock, avoiding oxidation which would make the product unsalable.

Be it wines, spirits, fruit juices or any bottled liquid, drying before the labeling stage is essential. Furthermore, removing the water residues under the cap allows for perfect conservation in stock, avoiding oxidation which would make the product unsalable. Also in this case the drying before the labeling phase after pasteurization phases, for example, is a decisive process for the quality of the product. Some critical points of these products are under the screw cap, or under the flip-part where water residues are more difficult to remove.

Also in this case the drying before the labeling phase after pasteurization phases, for example, is a decisive process for the quality of the product. Some critical points of these products are under the screw cap, or under the flip-part where water residues are more difficult to remove. In this case, drying on all sides of the product allows correct marking of the product and effective gluing of the straw, if present.

In this case, drying on all sides of the product allows correct marking of the product and effective gluing of the straw, if present.